Transportation

Aluminum is becoming increasingly important in the transportation industry, as manufacturers demand parts that are lighter, stronger and more resistant to corrosion. To meet this growing need, Pennex offers dedicated service to the transportation industry OEMs and suppliers. We can provide custom aluminum alloy extrusions and fabricated aluminum products for automotive, truck, trailer, truck body, locomotive, lift gates, and other applications. All work is done to meet customer and industry specifications and is tested as necessary to meet your regulatory requirements.

Keep reading for details about our full range of products and services, or contact our office directly to request a quote for an upcoming project.

Common and Specialty Alloys

We can produce aluminum billet in a range of sizes and alloys, including both standard and custom varieties. Our team includes trained metallurgists who have experience matching manufacturers’ requirements with products that will meet their specific requirements. Pennex’s two cast houses offer over 200 million lbs. of annual cast billet capacity, ensuring we can quickly turn around projects of any size and alloy.

Quality automotive, truck, truck body, and trailer components all start with the right raw materials. Our casting division complements and enhances our extrusion and fabrication capabilities, making us the ideal one-stop solution for all your manufacturing needs.

Extrusions

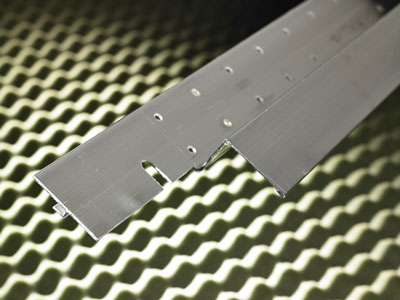

Pennex has a long history of producing custom aluminum extrusions for the transportation industry. We have an extensive catalog of standard die shapes and also offer custom die development services. Our two main facilities can produce extruded aluminum trailer and truck body components to include flooring and top and bottom rails with profile widths up to 16″, lengths up to 60’, and a maximum weight of 20 lbs. per foot. We can work with standard 6xxx series aluminum as well as customized materials — a unique quench system allows for higher-than-standard material properties in several alloy options.

Fabrications

Our extensive fabrication, machining and finishing capabilities include everything we need to turn an aluminum extrusion into a completed finished component. Specific fabrication services we offer include:

- Precision cutting and sawing

- Punching and notching

- Bending and forming

- CNC Machining, milling and drilling

- Painting, anodizing and other finishes

- Welding

- Assembly

All work is done to extremely high standards of quality. To meet the regulatory needs of the transportation industry, a wide range of testing services are available, too. We perform and document compression testing, flare testing and fold testing on fabricated aluminum components, and we can complete FAI and PPAP reporting to meet aerospace and other transportation industry requirements.

Moving the Transportation Industry to New Heights

Sophisticated materials play a key role in helping develop vehicles that are lighter, stronger, and more energy efficient. Aluminum can be found in everything from high-speed commuter trains to electric vehicle batteries.

To learn more about the benefits of this versatile material or for information about the role Pennex can play in your next project, contact our head-office directly by phone or email.