Aluminum and steel are some of the most popular materials in the world. Both are known for their versatility and strength, and you’ll find them across many industries and settings. From cars and buildings to window frames and kitchen utensils, aluminum and steel are constants in our daily lives.

The materials are also different in some respects. Each option has its strengths and weaknesses that make it a great choice for some uses but not as much for others. If you’re debating between aluminum vs. steel for a project, it can be tricky to select the one that will work best for you.

Strength and Malleability

A material’s strength and malleability are two physical properties to consider when selecting between materials. Strength measures how well it can withstand pressure without losing its original shape. Malleability is a material’s ability to be molded or altered without breaking. Malleability is usually tested by hammering or rolling the substance to see if it takes on a new shape or if it shatters.

Aluminum and steel have different levels of strength and malleability:

- Aluminum: When comparing aluminum vs. steel stiffness, aluminum is strong and malleable. Due to its lighter weight, you can mold aluminum into a wide variety of shapes. Aluminum also works well with other materials. It is often combined with other metals to create stronger alloys than aluminum on its own.

- Steel: Steel is one of the strongest materials on the planet, which is why it’s used in many bridges and buildings. Steel’s carbon content makes it heavier and stronger than aluminum. However, its power also causes steel to be less malleable than aluminum. Due to its heavier weight, it can’t be pushed to the same malleable limits. If you try to shape it into specific or delicate configurations, it could break altogether.

While steel is stronger, aluminum is more malleable. When considering steel vs. aluminum strength, it’s ultimately best to assess which property is more necessary for your project.

Weight

Steel and aluminum also differ by their weight. A material’s weight impacts many things, such as shipping costs and handling ability. It also tells how durable or long-lasting the material is likely to be.

Here are the differences in aluminum and steel’s weights:

- Aluminum: Aluminum is known for having the lighter weight of the two materials. Because it’s more lightweight, aluminum is often easier to handle during building or other projects. The lightweight tendency makes it a popular choice for the automotive industry, where it’s used in many vehicle components.

- Steel: Steel is heavier than aluminum. The carbon content makes the material much denser and more durable. Steel’s strength allows it to maintain its shape, even after tremendous pressure. While its weight makes steel sturdy, it also makes it more difficult to maneuver during construction. The extra weight might drive up your shipping costs when ordering materials.

Overall, steel has a much higher weight than aluminum. Keep this in mind as you choose the best material for your plans.

Corrosion

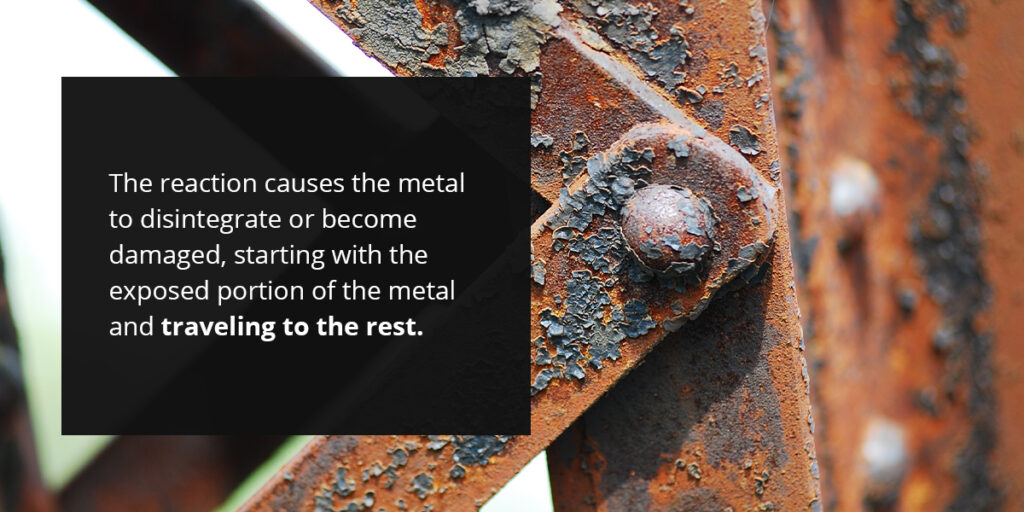

Corrosion is a natural process that occurs when metals react with air, water or similar substances. The reaction causes the metal to disintegrate or become damaged, starting with the exposed portion of the metal and traveling to the rest. The results could be severe if it harms your entire structure, which costs valuable time and money.

Aluminum and steel have different resistance levels to corrosion:

- Aluminum: One of aluminum’s many benefits is that it’s highly resistant to corrosion. Its oxide film protects against rust formation, which makes the material long-lasting. Its corrosion-resistant properties make aluminum a sustainable resource, too. With nearly 75% of produced aluminum still in use today, the material can be infinitely recycled. When you choose aluminum as a material, you know it will last a long while without any rust formation.

- Steel: Unlike aluminum, steel is less resistant to corrosion, especially if it is located in a wet or harsh environment, as steel will form rust after reacting with water or other substances. You can treat steel with paint or other protective coatings to prevent severe corrosion, but rust formation is still likely.

Keep corrosion resistance in mind when choosing between these two substances. Luckily, there are ways to further prevent corrosion for both materials, such as extra protective coats and paints.

Applications

Aluminum and steel are used for different industries and applications. While both are highly versatile, sometimes one substance works better in a particular field. Here’s a look at the typical applications of steel and aluminum.

Steel Applications

As one of the most popular materials in the world, you can find steel in a variety of industries. These include:

- Construction: Steel’s extreme durability makes it a popular choice for the construction industry. You can commonly find it in bridges, skyscrapers and roads. Many buildings use steel in their infrastructures, such as reinforcing bars or other structural sections.

- Heating: Manufacturers use aluminum in many HVAC systems due to its heat transference.

- Appliances: Many household appliances contain steel, like microwaves, washing machines, refrigerators or coffee makers. It’s also found in kitchen utensils.

- Medical or pharmaceutical: Steel products are popular in the pharmaceutical industry because of their durability. It can withstand exposure to many different chemical types and tolerates extremely high temperatures, like those needed for product sanitation.

Aluminum Applications

Aluminum’s ability to be extruded in various shapes means it has different applications in many industries. Its versatility, accessibility and malleability make it a frequent choice in industries like:

- Automotive: Manufacturers use aluminum in almost every automotive component, from the vehicle body and wheels to electrical wiring and engine parts. It boosts vehicles’ fuel efficiency and is a sustainable product, rapidly growing in car production popularity.

- Signage: Aluminum is one of the most popular road and business sign materials. Because it resists corrosion and is lightweight, it is a great material for durable signage.

- Building or construction: Like steel, aluminum is also used in the construction industry. Its corrosion resistance makes it ideal for exterior uses, like roofs, walls, railings and window linings.

- Electronics: Aluminum also conducts electricity well, making it a good fit for electronics. Manufacturers use aluminum in computer parts, device cases and even power lines.

Because you can use aluminum and steel in a wide variety of industries, it’s best to find the material that suits your specific application. If both materials are useful for your goals, weigh the other properties like weight, malleability and corrosion resistance to make your final choice.

Contact Pennex Aluminum Company for All Your Aluminum Needs

Since 1979, Pennex Aluminum Company has supplied high-quality aluminum products for customers across the United States. Aluminum is a highly durable and malleable material that you can use in automotive, transportation, construction and many other industries. We pride ourselves on providing premier quality aluminum for customers.

Contact us today to learn how we can supply the best aluminum solution for your project.